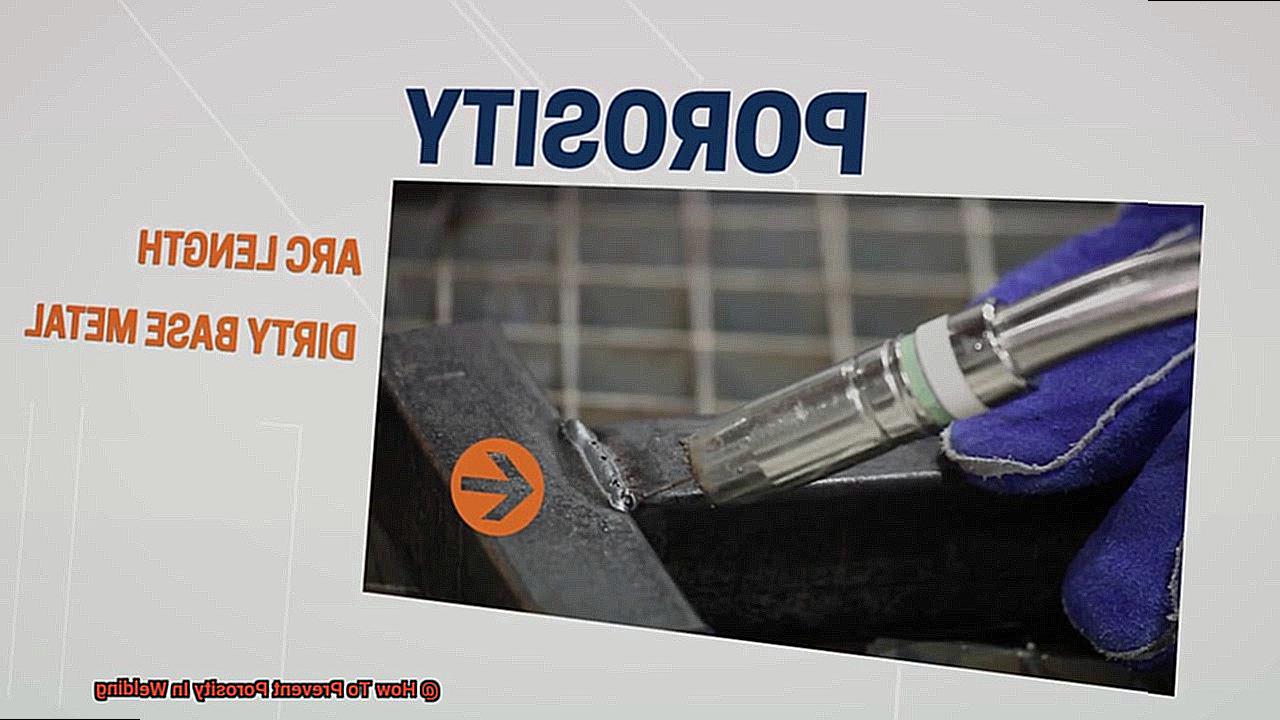

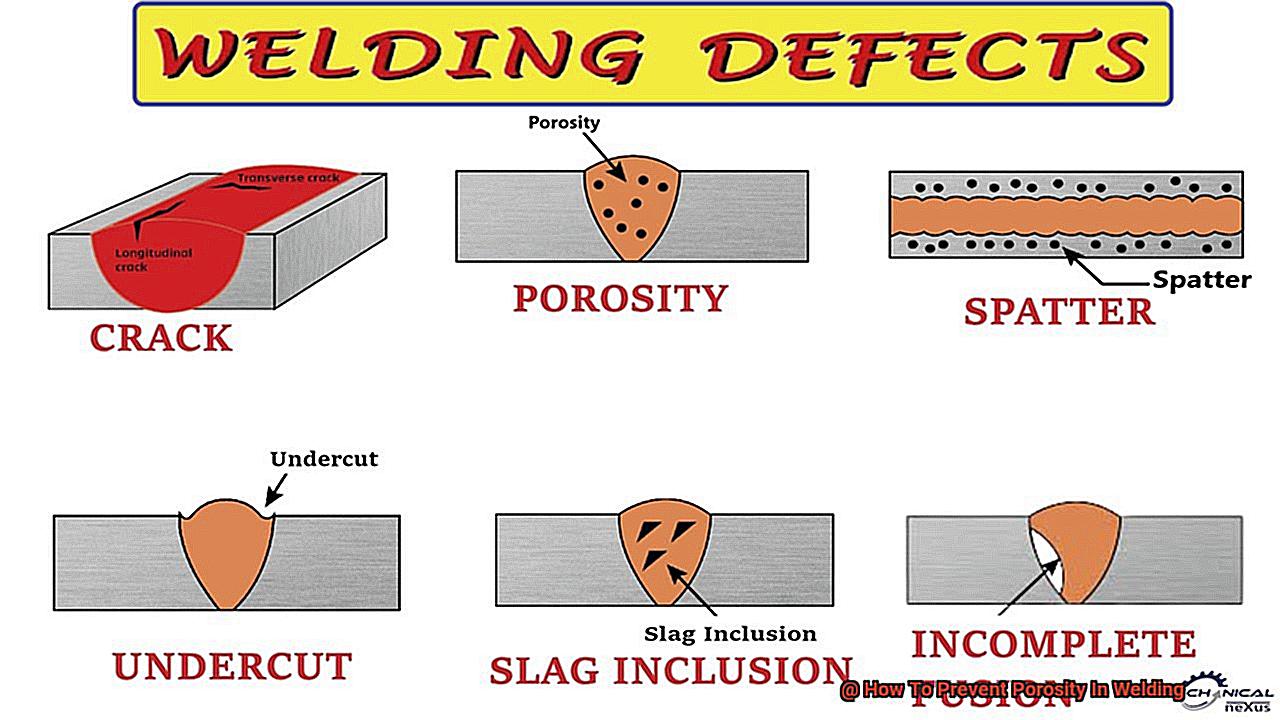

How To Prevent Porosity In Welding - To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. Proper welding and workspace preparation techniques can help. Follow these 4 simple tips to prevent porosity in welding. To prevent porosity in welding, it’s essential to follow proper welding procedures and use clean materials free from contaminants. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Check your gas flow 3. By taking some of the following steps, you will reduce the chance of porosity. Now that we know the causes of porosity, what can we do to prevent it? Welding variables such as shielding gas, surface. Welders should maintain proper shielding gas.

Follow these 4 simple tips to prevent porosity in welding. To prevent porosity in welding, it’s essential to follow proper welding procedures and use clean materials free from contaminants. Check your gas flow 3. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Proper welding and workspace preparation techniques can help. Welders should maintain proper shielding gas. Welding variables such as shielding gas, surface. Now that we know the causes of porosity, what can we do to prevent it? To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. By taking some of the following steps, you will reduce the chance of porosity.

To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. Check your gas flow 3. Now that we know the causes of porosity, what can we do to prevent it? By taking some of the following steps, you will reduce the chance of porosity. Proper welding and workspace preparation techniques can help. Welders should maintain proper shielding gas. Follow these 4 simple tips to prevent porosity in welding. To prevent porosity in welding, it’s essential to follow proper welding procedures and use clean materials free from contaminants. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Welding variables such as shielding gas, surface.

How To Prevent Porosity In Welding? The Welding Guru

Check your gas flow 3. Now that we know the causes of porosity, what can we do to prevent it? To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. Welders should maintain proper shielding gas. Welding variables such as shielding gas, surface.

Porosity in Welding What is it? And How to Prevent It

Welding variables such as shielding gas, surface. By taking some of the following steps, you will reduce the chance of porosity. Welders should maintain proper shielding gas. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Follow these 4 simple tips to prevent porosity in welding.

How To Prevent Porosity In Welding? The Welding Guru

To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Proper welding and workspace preparation techniques can help. To prevent porosity in welding, it’s essential to follow proper welding procedures and use clean materials free.

How To Prevent Porosity In Welding? The Welding Guru

Proper welding and workspace preparation techniques can help. Now that we know the causes of porosity, what can we do to prevent it? To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. Welders should maintain proper shielding gas. Check your gas flow 3.

Porosity in Welding What is it? And How to Prevent It

Follow these 4 simple tips to prevent porosity in welding. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. To prevent porosity in welding, it’s essential to follow proper welding procedures and use clean.

How To Prevent Porosity In Welding? The Welding Guru

Welders should maintain proper shielding gas. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Check your gas flow 3. To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. Now that we know the causes of porosity, what can we do to prevent.

How To Prevent Porosity In Welding? The Welding Guru

To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. By taking some of the following steps, you will reduce the chance of porosity. Now that we know the causes of porosity, what can we do to prevent it? Porosity in welding is associated due to metallurgical changes that take place during the welding.

Porosity in Welding What is it? And How to Prevent It

Follow these 4 simple tips to prevent porosity in welding. Check your gas flow 3. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Welders should maintain proper shielding gas. Now that we know the causes of porosity, what can we do to prevent it?

Porosity in Welding 5 Amazing Ways to Prevent it

To prevent porosity in welding, it’s essential to follow proper welding procedures and use clean materials free from contaminants. Welders should maintain proper shielding gas. By taking some of the following steps, you will reduce the chance of porosity. Proper welding and workspace preparation techniques can help. Now that we know the causes of porosity, what can we do to.

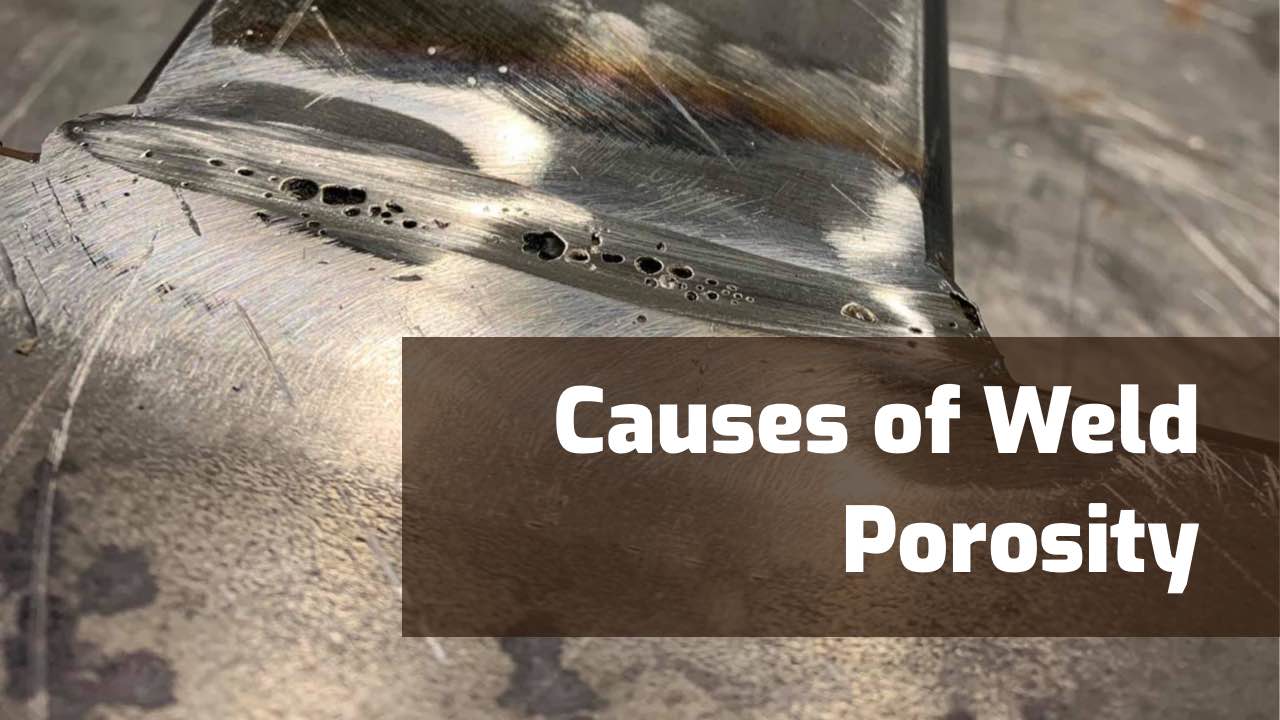

What Causes Weld Porosity In MIG Welding?

To prevent welding porosity, it is crucial to remove the porous section and prevent it entirely. Follow these 4 simple tips to prevent porosity in welding. Proper welding and workspace preparation techniques can help. Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Welding variables such as shielding gas, surface.

Proper Welding And Workspace Preparation Techniques Can Help.

Welding variables such as shielding gas, surface. Check your gas flow 3. To prevent porosity in welding, it’s essential to follow proper welding procedures and use clean materials free from contaminants. Welders should maintain proper shielding gas.

To Prevent Welding Porosity, It Is Crucial To Remove The Porous Section And Prevent It Entirely.

Now that we know the causes of porosity, what can we do to prevent it? Porosity in welding is associated due to metallurgical changes that take place during the welding in the weld metal. Follow these 4 simple tips to prevent porosity in welding. By taking some of the following steps, you will reduce the chance of porosity.